Business

Make a Future Silicone

Silicone Process

Silicone Processing

Silicone?

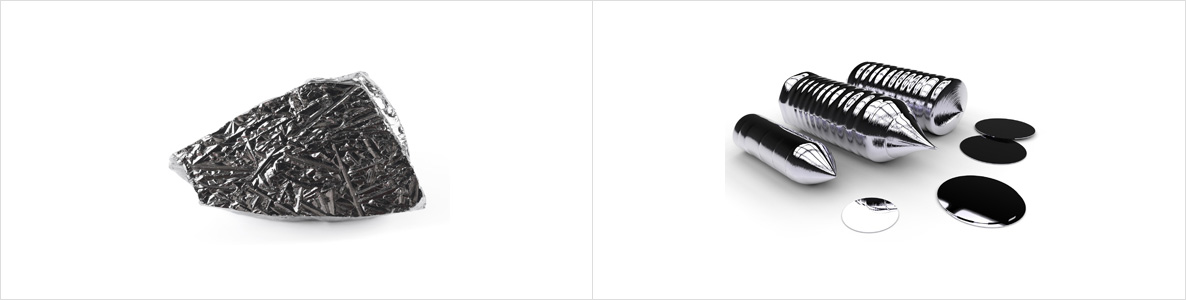

Silicone is a polymer made by extracting silicon (Si) from stone and sand (SiO₂), and linking it through siloxane bonds (Si-O-Si). This molecular structure gives silicone both inorganic and organic properties. That is, due to the inorganic characteristics from the siloxane bond (Si-O-Si), it offers excellent heat resistance, chemical stability, abrasion resistance, and cold resistance; and due to its organic nature, it provides high reactivity, solubility, and workability. Silicone does not exist in nature and is artificially synthesized. Depending on its form, it can be classified as oil, rubber, or resin, and based on usage purposes, it is blended with various materials to create a wide range of products.

Silicone Manufacturing Process

-

Fluids -

Silanes -

Elastomers -

Resins

-

HCR (High Consistency Rubber) -

LSR (Liquid Silicone Rubber) -

RTV (Room Temperature Vulcanizing, FS/DM) -

Silicone Oil -

EMULSION

Silicone is widely used as a core material across various industries.

-

Baby products industry

Baby products industry -

Household goods industry

Household goods industry -

Medical industry

Medical industry -

Cosmetics industry

Cosmetics industry -

Electrical and electronics industry

Electrical and electronics industry -

Automotive industry

Automotive industry -

Aerospace industry

Aerospace industry